If you’re looking for something that can effectively safeguard your floors against water damage, scratches, and general wear and tear, there are various coatings that you can try. Polyaspartic, however, is an outstanding coating choice. Available in a range of colors, it’s known to be virtually compatible with any floor surface.

What Is a Polyaspartic Coat?

Polyaspartic floor coating is an advanced protective finish renowned for its exceptional durability and versatility. These coatings are formulated from polyaspartic esters and offer remarkable resistance against water damage, abrasions, chemicals, and UV radiation.

What Are the Benefits of Polyaspartic Coats?

Polyaspartic coating can give your floor:

1. Durability

Polyaspartic coatings are incredibly durable, offering robust protection against abrasions, impacts, and even chemical spills. This makes them ideal for high-traffic areas and industrial settings where floors are subjected to heavy use.

2. UV Resistance

Polyaspartic coats exhibit impressive resistance to UV radiation, which means they won’t yellow, fade, or degrade when exposed to sunlight. This makes them suitable even for outdoor applications.

3. Chemical Resistance

Polyaspartics serve as effective barriers against chemicals, oils, and solvents. This rare attribute is valuable in areas where spills or chemical exposure is likely to happen at any given time.

4. Customizable Aesthetics

Since they come in various colors, finishes, and patterns, it’s easy to come up with personalized polyaspartic coatings. They give you the flexibility to achieve the desired look for your floor, depending on your taste or style.

5. Low VOC

This is another unique feature of polyaspartic floor coatings. A low volatile organic compound (VOC) can lead to improved indoor air quality, which is especially beneficial for residential homeowners.

How Do You Apply Polyaspartic Coating?

When applying polyaspartic coating on your floor, follow these steps:

1. Prepare the target surface.

Begin by thoroughly cleaning the substrate to remove dirt, dust, and contaminants. Also, repair any cracks or imperfections that you find on the surface. A smooth and clean surface is essential for proper adhesion of the coating.

2. Mix the coating well.

Use the recommended mixing ratios for the coat and ensure that you get a thorough blend. Typically, this involves mixing two components by volume, Part A (resin) and Part B (hardener).

3. Cut in the edges.

Use a brush or roller to apply the coating along the edges and corners of the floor, creating a border in the process. This technique, known as “cutting in,” ensures a clean and even application near the walls and hard-to-reach areas.

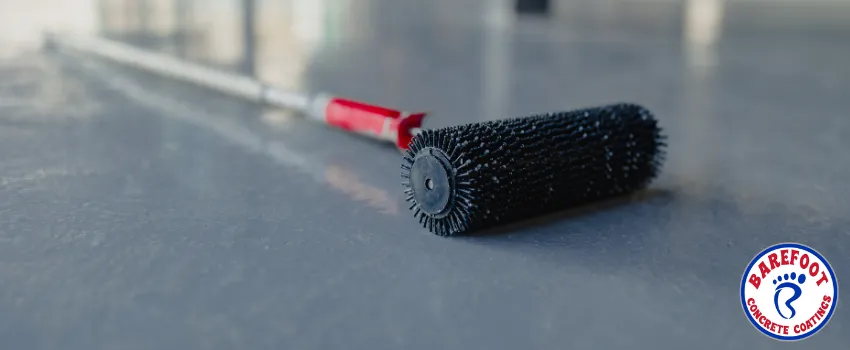

4. Roll on the coating.

Using a roller with an extension pole, apply the coating evenly across the floor surface. Work in small sections, maintaining a wet edge to prevent visible seams from being created.

5. Get a consistent coat application.

Use a gauge rake to spread the coating evenly and maintain the desired thickness. This step is crucial for achieving a uniform finish.

6. Check for air bubbles.

After applying the coating, carefully inspect the surface for any air bubbles. If these are present, remove them with a roller that has a looped cover.

7. Let the coat dry completely.

Allow the coating to cure per the manufacturer’s recommendations. The timeframe for this may vary based on factors such as temperature and humidity.

8. Inspect the coating.

After the curing is complete, examine the coated surface one more time for signs of defects. Touch up any area that you think requires further attention.

Does Polyaspartic Need a Primer?

In many cases, using a primer before applying polyaspartic coating is recommended. This is because primers create a bonding layer between the substrate and the coating, enhancing the latter’s ability to adhere effectively. Primers also help improve the durability and performance of the coating, especially in challenging environments.

How Many Coats of Polyaspartic Do I Need?

The number of polyaspartic coats required depends on several factors, including the condition of the substrate, the desired level of durability, and the manufacturer’s recommendations. In most cases, a single coat of polyaspartic is sufficient to get a uniform finish. However, applying two or three coats is advisable for areas exposed to heavy wear.

Key Takeaway

Carefully following the steps in applying polyaspartic coating to your floor can lead to a visually-appealing finish. For additional coats, it’s best to follow the manufacturer’s guidelines and determine the specific needs of your space. Doing so will ensure you achieve the desired balance between protection and appearance.

For a more professional floor finish, however, you should consider getting in touch with an experienced coating company. They can expertly handle all floor types and provide you with excellent results.

Get top-notch polyaspartic concrete coating services from Barefoot Concrete Coatings.

The flooring of any given property is among the most susceptible to damage. Protect them with the right coating from Barefoot Concrete Coatings.

We offer quality polyaspartic coating in Alpine, UT, and ensure that your floors last long and look beautiful for years. Call us today.